Tribological mechanisms, process optimization and surface design

Tribology covers friction, wear and lubrication is a part of research and development at the TriboMAN. Comprehensive fundamental research within tribology and manufacturing is an important subject. TriboMAN plays an important key role to bridge valuable results from TriboMAN application-oriented researches and innovations to industrial manufacturing processes. Industrial applications include metal forming and machining under cold and hot working conditions.

Projects

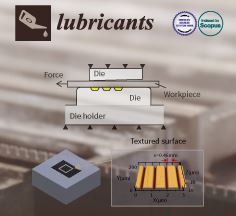

Development and testing of tailored tool surfaces for sheet-metal forming

This study describes measures taken to minimize or substitute environmentally hazardous lubricants applied in sheet metal forming processes by less harmful lubricants or not applying lubricant at all. The breakdown of lubricant film often leads to galling, and therefore application of the hazardous lubricants has spurred industrial interest. In order to face a serious challenge in trying to stimulate less consumptions of such hazardous lubricants, the PhD project was intended to lead to improvements in resistivity towards galling in sheet metal forming by studying three different subjects; compressibility of lubricants, application of structured tool surfaces and application of anti-seizure tool coatings.

To know more about the topic, please read the following publications

- Sulaiman, M. H. B. (2017). Development and testing of tailored tool surfaces for sheet metal forming.

- Sulaiman, M. H., Christiansen, P., & Bay, N. (2017). The influence of tool texture on friction and lubrication in strip reduction testing. Lubricants, 5(1), 3.

- Sulaiman, M. H., Christiansen, P., & Bay, N. (2017). Influence of tool texture on friction and lubrication in strip reduction. Procedia Engineering, 207, 2263-2268.

- Sulaiman, M. H., Christiansen, P., & Bay, N. (2017, September). A study of DLC coatings for ironing of stainless steel. In Journal of Physics: Conference Series (Vol. 896, No. 1, p. 012031). IOP Publishing.

- Sulaiman, M. H., Christiansen, P., Bay, N., & Carbon, D. L. (2018). A study of anti-seizure tool coatings of ironing of stainless steel. Jurnal Tribologi, 17, 1-14.

- Hafis, S. M., Christiansen, P., Martins, P. A. F., & Bay, N. (2016). Determination of lubricant bulk modulus in metal forming by means of a simple laboratory test and inverse FEM analysis. In 7th International Conference on Tribology in Manufacturing Processes (ICTMP 2016) (pp. 316-323).

- Sulaiman, M. H., Christiansen, P., & Bay, N. (2019). An experimental compression test of lubricants with direct measurement of lubricant pressure build-up. Jurnal Tribologi, 20, 51-64.

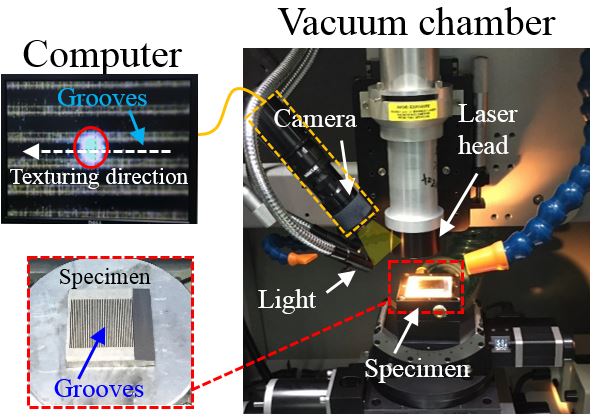

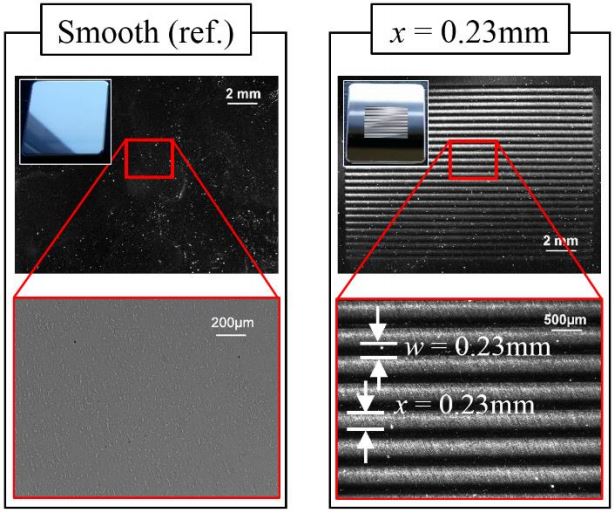

Contact mechanisms between workpiece and tailored tool surfaces influencing lubrication and friction in tribologically severe manufacturing processes

Tailored tool surfaces show promise as alternative to replace chlorinated oils in sheet-metal forming. The tool surfaces have been tailored by micro-groove as well as coating to look into its potential under dry and minimal lubrication amount of less harmful lubricants. Tribologically severe strip reduction test, emulates industrial ironing, was used to better understand the effects of tailored tool surfaces for severe forming conditions. Investigated tailored tool surfaces have shown a positive result leading to improve lubrication.

To know more about the topic, please read the following publications

- Sulaiman, M. H., Farahana, R. N., Ridzuan, M. J. M., Jaafar, H., Tajul, L., & Wahab, J. A. (2019). Manufacturing strategies and tribology of tailored tool surface topographies for enhanced lubrication in metal forming. In Proceedings of 3rd Mytribos Symposium (pp. 47-51).

- Sulaiman, M. H., Kamel, M. U., Farahana, R. N., & Wahab, J. A. (2019, November). Design and characterization of textured surfaces for metal forming applications. In IOP Conference Series: Materials Science and Engineering (Vol. 670, No. 1, p. 012056). IOP Publishing.

- Sulaiman, M. H., Zaid, M. F. S., Farahana, R. N., & Ridzuan, M. J. M. (2019, November). CFD analysis of hydrodynamic lubrication effects of micro textured surface. In IOP Conference Series: Materials Science and Engineering (Vol. 670, No. 1, p. 012061). IOP Publishing.

- Sulaiman, M. H., Farahana, R. N., Mustaffa, M. N., & Bienk, K. (2019, November). Tribological properties of DLC coating under lubricated and dry friction condition. In IOP Conference Series: Materials Science and Engineering (Vol. 670, No. 1, p. 012052). IOP Publishing.

- Sulaiman, M. H., Farahana, R. N., Bienk, K., Nielsen, C. V., & Bay, N. (2019). Effects of DLC/TiAlN-coated die on friction and wear in sheet-metal forming under dry and oil-lubricated conditions: Experimental and numerical studies. Wear, 438, 203040.

Engineered Tool Surface (ETS) for metal stamping

Tool wear is a gradual failure of metal stamping due to too hot tool/workpiece surface. Tools affected always require a necessary tool replacement as a result of short tool service life. Engineered Tool Surface (ETS) is studied to reduce friction and wear. This project is a collaborative work with industry. The methodology includes: 1) numerical studies of the process parameters on the ETS; 2) experimental studies on ETS at varying loads, temperatures, and speeds.