Tribology is the science of wear, friction and lubrication, and encompasses how interacting surfaces and other tribo-elements behave in relative motion in natural and artificial systems.This includes bearing design and lubrication.

Tribology is not an isolated science, but rather a complex, multidisciplinary endeavor where advances are made by collaborative efforts of researchers from fields including mechanical engineering, manufacturing, materials science and engineering, chemistry and chemical engineering, physics, mathematics, biomedical science and engineering, computer science, and more.

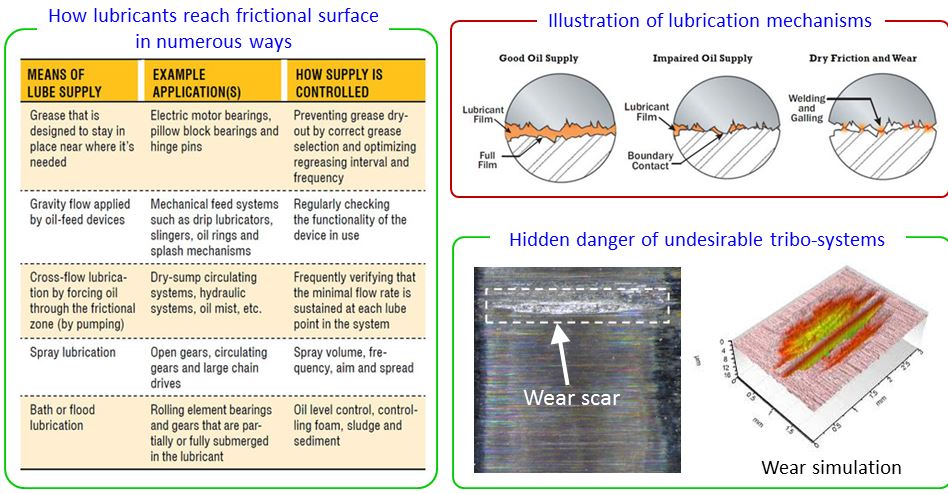

Solution of tribological problems starts with a detailed investigation on the tribological system with all influence factors that are involved. From this, it can be deduced what frictional conditions and wear mechanisms are to be reckoned with and when they come into play.

In practice, more than one of these effects is active at any given time or they occur consecutively during the wearing process. However, it is usually one of them that plays the predominant part in failure due to wear.

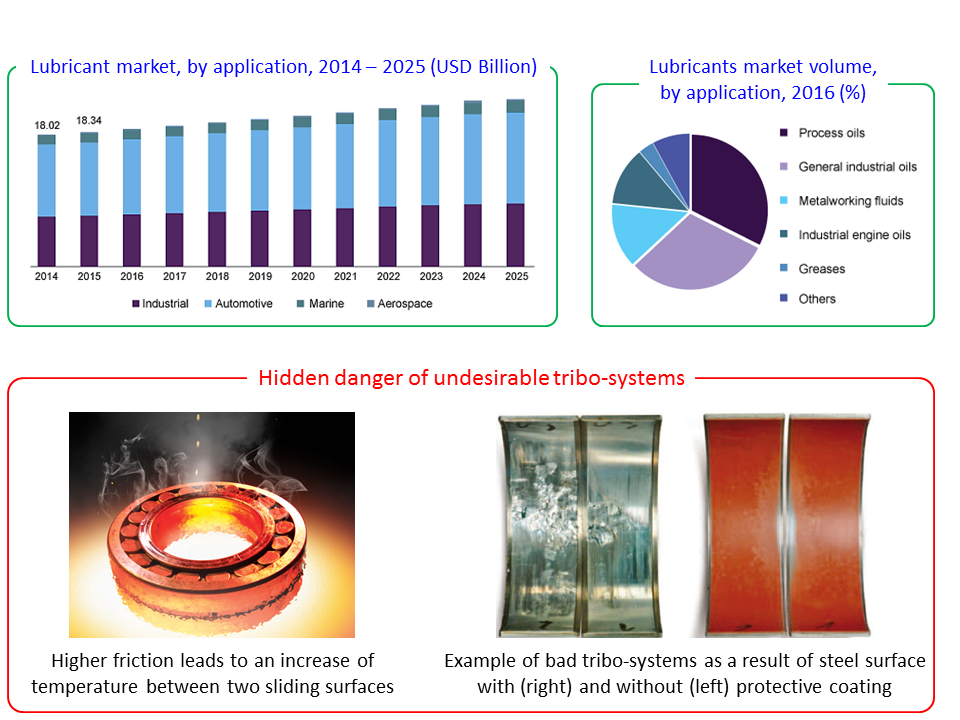

Research shows that every tribological system can be optimised by selecting one of the right tribo-elements, such as coating, lubricant, surface modification and tool material.

- Science of friction, wear and lubrication.

- Derived from the old Greek word “tribos”, which means “rubbing”.

- The science and technology of interacting surfaces in relative motion and of related subjects and practices.

- Lubrication and lubricants

- Generation and transmission of forces at the interface

- Response of materials to the force generated at the interface

- Design of tribological systems

Solid surfaces

Characteristics of solid surfaces affect the area of contact, wear, friction and lubrication features.

Surface roughness

Affect the behaviour of mating surfaces when they come in contact, results from irregularities left by the cutting or shaping tools.

Surface contact

Interaction between two engineering surfaces and initiates contact spots that form the area of contact between these two surfaces.

- A result of energy dissipation at the sliding interface.

- The resistance to relative motion between two bodies in contact.

- When objects touch, there are forces between them.

- Friction force, F= ∂W/∂s, where F and s are vectors.

- A result of energy dissipation at the sliding interface.

- The resistance to relative motion between two bodies in contact.

- When objects touch, there are forces between them.

- Friction force, F= ∂W/∂s, where F and s are vectors.

- Introducing a substance between two relatively close surfaces in relative motion, in order to reduce the volume of friction and wear.

- Lubrication can be solid or fluid.

- Solid film is a substance such as powder or solid material used to reduce wear and friction effect.

- Fluid film can be liquid or gaseous, the thin film reduces contact and the thick one can prevent contact between lubricated surfaces.